RFQM series airflow mill

RFQM series jet mill, yingkou ruifeng powder equipment co., LTD., according to many years of rich experience, the data such as aerodynamics, fluid mechanics, and combined with the various problems in practical production, and the basis for optimizing the improvement of independent research and development models, practical, high yield, and widely applied to fine talc, calcite and other non-metallic mineral powder processing, the finished product fineness of between 1 to 30 microns.

The working principle of

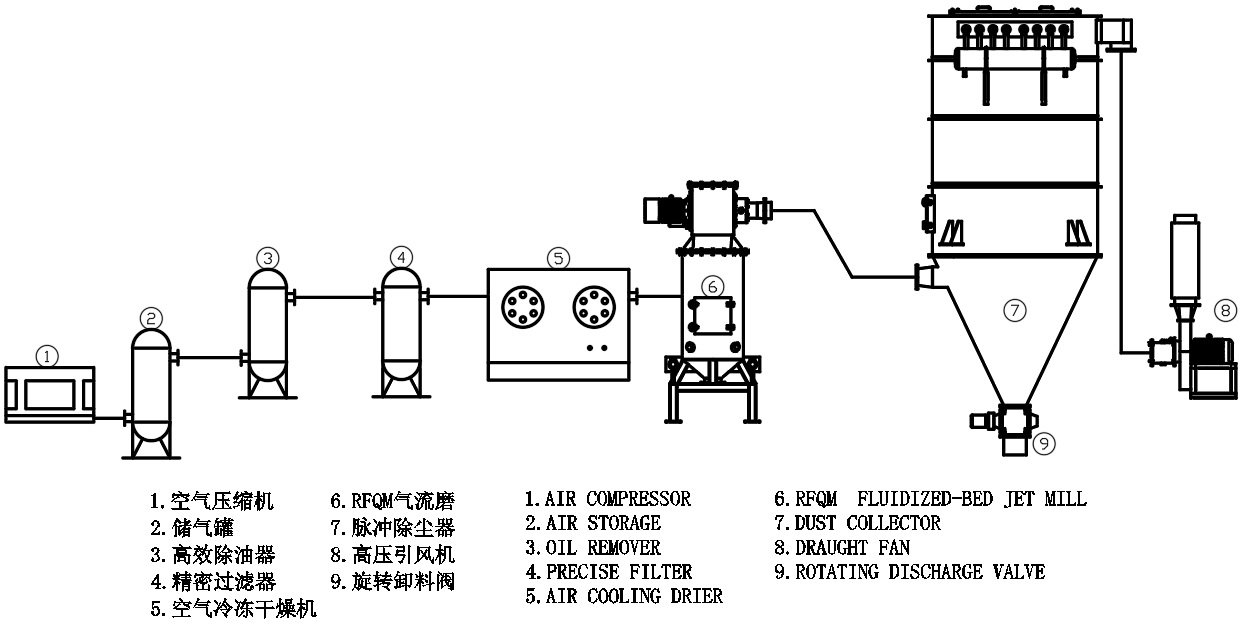

Fluidized bed air mill (hereinafter referred to as the air mill) is a high-speed air flow to achieve dry material crushing equipment. It consists of grinding body, nozzle, classifier and other parts. The material enters the grinding body's internal comminution area through the inlet, and the compressed air is injected into the grinding body at a high speed through the supersonic nozzle. The coarse particles are accelerated in the supersonic jet, and smash into each other at the intersection of the nozzles. The crushed material enters the grading area with the updraft. Under the action of the grading machine, the coarse material larger than the graded particle size returns to the inner part of the grinding body for further impact and crushing. The fine particle products in line with the graded particle size are collected by the dust collector through the grading wheel through the pipeline. After the superfine powder enters the dust collector through the sealed pipe, it is discharged from the packing system. Dust enters the dust collector, passes through the cloth bag filter (Germany bedafu filter bag) after the gas, in the induction fan under the action of extraction, exhaust into the atmosphere. The amount of dust discharged is lower than the dust emission standard set by the national environmental protection department.

Performance advantage

1. The classifier adopts new technology and the specially designed classifier has a resistance lower than the original classifier by more than 30%, which correspondingly reduces the energy consumption of the fan by 20-30%.

The particle size distribution is concentrated, which avoids the over-grinding of powder in the machine. Compared with the old airflow grinding, the energy saving is 20~30%, and the output is 30~40% higher.

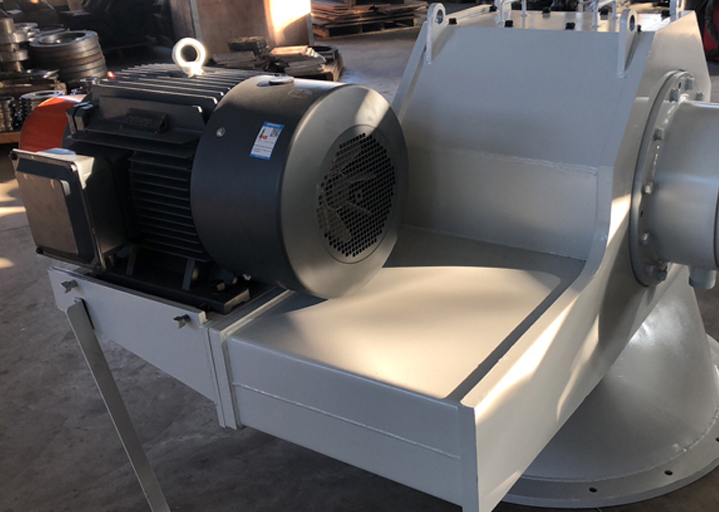

2. Adopt independently designed spindle structure of classifier. The new structure design has higher strength, higher speed, longer service life, and more convenient lubrication and maintenance.

3. The system operation adopts the touch screen interface for operation, PLC program automatic control, classifier, main fan and feeder are all driven and controlled by Japanese yaskawa frequency converter, and the feeding system can provide faster and more accurate feeding according to the system pressure difference, current and other data. The cleaning control of the pulse dust collector and the speed control of the main fan are all fully automatic according to the pressure of the system and the pressure difference, so as to ensure the stable and efficient operation of the whole system。

4. Less wear and tear. Since the main pulverizing action is the impact and collision between the materials, the high-speed material particles rarely collide with the wall of the grinding body, which can be used to pulverize the materials with mohs hardness above grade 9.

5. Inflammable and explosive materials can be crushed by inert gas as working medium.

6. No pollution. Because the material is driven by airflow collision and crushing, not into the medium, so in the crushing process of the material will not constitute pollution.

7. Output :50 ~ 5000 kg/h; Fineness: d97=3 ~ 45 microns;

Scope of application

This machine is widely used in talc, brucite, barite, magnesium hydroxide, lithium iron phosphate and other non-metallic minerals, electronic materials, chemical industry, new materials, abrasive, refractory, rare earth, ceramics, metal powder, toner, pesticide, medicine.

12/5000

RFQLM series jet mill

| Technical parameters of different models RFQM series airflow mill | |||||

|---|---|---|---|---|---|

| Model parameters | QLM700 | QLM800 | QLM900 | QLM1000 | QLM1200 |

| Particle size d97: mum | 6-100 | 8-100 | 8-100 | 10-100 | 10-100 |

| Grinding gas m3/min | 20-30 | 40-50 | 60-70 | 80-90 | 120-140 |

| Air pressure Mpa | 0.6-1.0 | 0.6-1.0 | 0.6-1.0 | 0.6-1.0 | 1.6-1.0 |

| Graded power kw | 15/18.5 | 22/30 | 30/37 | 37/45 | 55/75 |

Flow diagram of airflow mill