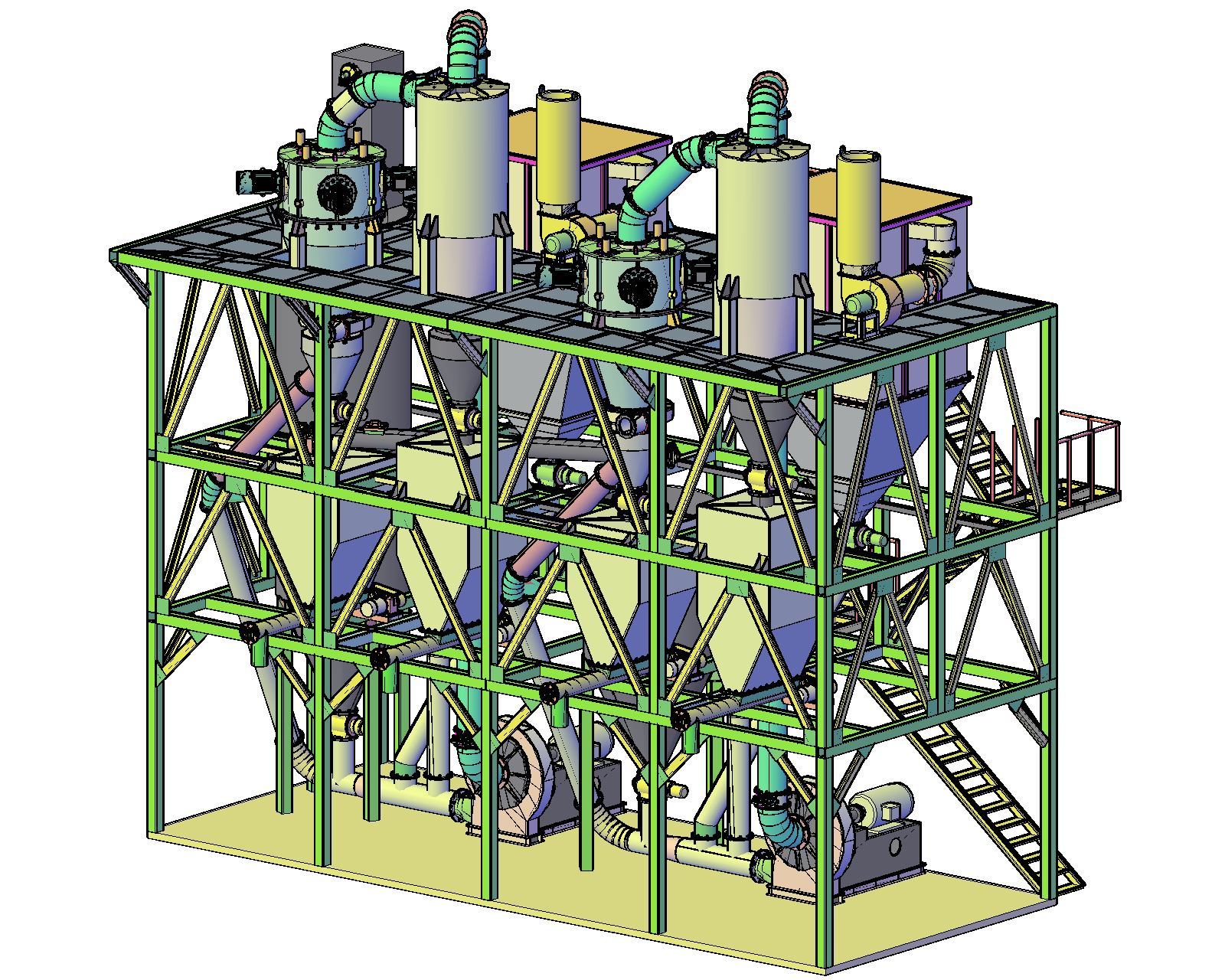

RFEF series secondary classifier

RFEF series secondary classifier is a mature grading technology adopted by yingkou ruifeng powder equipment co., ltd. and combined with the supporting RFLM series fine powder vertical mill grading technology produced by our company to solve the current problems of poor grading effect and low output of ordinary classifier. This series of secondary grading, 1.5~30 muon, 2 muon content up to 90%.

The working principle of

Feed screw conveyor will be stored in the raw materials warehouse of powder materials, using computer control in a fixed flow into the feeding tube, and before entering the classifier, powder material will be fully with the main flow of fan is mixed, with the main flow of material into the first grader at the bottom of spiral case, the use of spiral case structure will change into the volute airflow direction, and form vortex under the action of the spiral force, make into the next shell the main flow of spiral flow, under the action of centrifugal force for powder material classification, coarser particles powder will first tell, not into the shell and coarse particle powder falling from the bottom of the classifier, which resulted after for grading.

The secondary airflow is inhaled from the bottom of the lower shell, and the remaining fine powder is selected from the coarse powder. The rest of the airflow containing the finer powder is carried into the rear grading zone, where the powder is selected by an automatic classifier equipped with three or more grading wheels at the grading outlet. Powder in the classification zone, received the centrifugal force, the fluid resistance, and under its own gravity, is greater than the grading round powder will be able to point back to the shell, powder is less than help with airflow out of the classifier, the fan will be in the gas powder grade your machine, with the impulse type dust collector to collect for finished products, part of the gas from the exhaust duct equipment expelled into the atmosphere, the air is recycled as the primary air flow, in

Performance advantage

1. Uniform particle size distribution. It can be adjusted and controlled according to the required bundling point to maintain a very narrow particle size distribution.

2. Products are stable, continuous and reliable. The product fineness can be arbitrarily adjusted by frequency conversion to adjust the speed of the grading wheel or the opening of the air valve.

3. It can be used for large-scale industrial grading production with strong eddy current grading design, horizontal placement of graded impeller and multi-graded wheel mechanism design, which is more suitable for large-scale industrial grading production of 400-8000 mesh micro powder.

4. An independent grading system can be set up for separate use. Suitable for direct connection of all kinds of grinding equipment (such as ultra-fine vertical mill, ball mill, vibration mill, airflow mill, impact mill, mixing mill, etc.), the combination of closed circuit continuous ultra-fine powder production system.

5. The complete grading system adopts PLC touch screen intelligent control, which can realize real-time display, parameters, indicators, temperature, output, fineness, etc., and can be adjustable and controllable. Due to the mature technology of our company, we can achieve perfect connection with RFLM series ultrafine vertical mill, or independently become a set of central control system.