Project | ray FengLi grinding - leading powder equipment and solution provider in China

POSTED TIME:2018-12-21 PAGE VIEW:3226Yingkou Ruifeng Powder Equipment Co., Ltd. is located in the beautiful shore of the Bohai Sea - Liaoning Yingkou. The geographical location of the company is superior, adjacent to the airport, high-speed railway, port and Shenyang-Hai expressway, located in the hub position, land and water transportation is very convenient.

The company is mainly engaged in powder engineering technology research and development and powder engineering equipment manufacturing, is a set of research and development, manufacturing, sales as one of the high-tech enterprises. We have carried out in-depth research on ultrafine powder vertical mill, classifier, powder automatic quantitative packaging machine, powder industrial control automation equipment, and continue to absorb and learn advanced technology at home and abroad, combined with the market customer demand to provide users with a complete powder equipment solutions. Company has a senior excellent r&d team, seiko quality gauri powder grinding, powder conveying, such as powder packaging equipment, but also relying on the powerful ability of equipment manufacturing and perfect engineering services has been successful product almost covering the whole country more than 30 provinces, municipalities and autonomous regions as well as Japan, Korea, Pakistan, and other countries and regions.

We strictly implement the principle of total quality management (PDCA) and provide EPC general contracting services to customers. To provide customers with technical consultation, engineering design, equipment manufacturing, procurement, automation control, construction management and project management services. Companies adhering to the "integrity based, innovation, mutual benefit and win-win" philosophy of the manager, pay attention to product quality, pay attention to customer service, won the trust of a large number of loyal customers. Ruifeng people will, as always, "strive to be the leader of China's leading powder equipment and solutions" this enterprise vision as a lifelong goal, to make important contributions to our country's powder industry!

RFLM series ultrafine vertical mill

RFLM series ultrafine powder vertical roller grinding machine, Ruifeng Powder Equipment Co., Ltd. depends on many years of ultrafine powder technology, as well as through in-depth study of Germany, Japan and other foreign ultrafine powder technology, fully understand the needs of users, understand the pain points of the industry. With professional design concept, through in-depth research and development of international first-line brand parts suppliers, we have launched a number of ultrafine powder grinding equipment, which is widely used in large-scale ultrafine powder processing fields such as calcite, barite and talc.

The working principle of

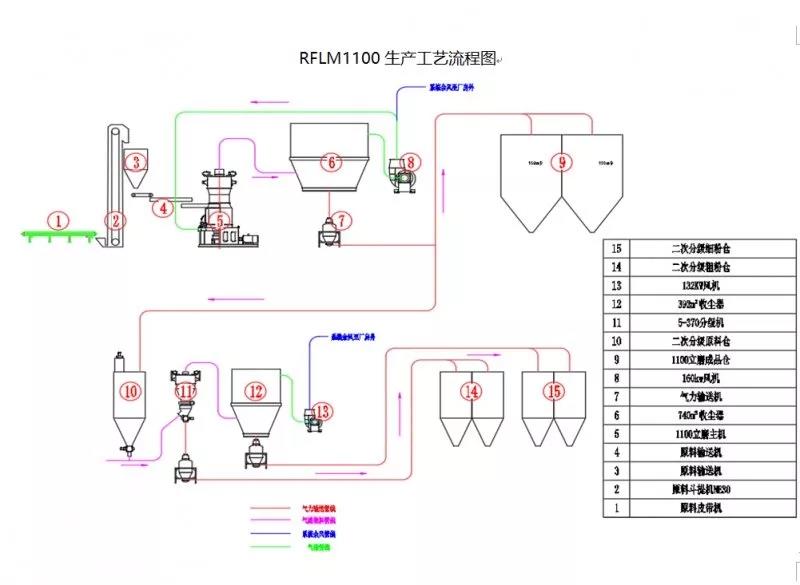

The main motor drives the grinding disc to rotate through the reducer. The material enters the main machine of the vertical mill through the screw conveyor and falls into the center of the grinding disc under the action of gravity. At the same time, the air generated by the fan enters the main machine from the inlet.

Under the action of centrifugal force, the material moves evenly from the center of the grinding disc to the edge. When it passes through the roller on the grinding disc, it is crushed by the grinding roller. The large material is crushed directly, and the fine material is extruded to form a material layer for intergranular crushing.

The crushed material continues to move to the edge of the grinding disc until it is taken away upward by the strong air flow guided by the tuyere ring on the periphery of the grinding disc. The coarser material falls back to the grinding disc due to its own gravity and is ground again. Fine material, with the air currents to rise into the host at the top of the hierarchical system of classification, screening in classification under the action of rotor blade, coarser material can not be passed, and again be blades to strike live inside the mill grinding, qualified fine powder with the air out of the grading system, through external pipe into the dust removal system, and then the filter will air separation and materials, after collection, That is the finished product.

In addition, the debris and large particles in the material will be scraped into the slag discharge mouth by the scraping plate and discharged into the grinding body when grinding, so as to effectively ensure the quality of the finished product.

In addition, the pressure of the grinding roller can be adjusted by adjusting the pressure of the hydraulic system, which can adapt to the material requirements of different hardness within a certain range. By adjusting the rotor speed of the multi-rotor classification system, the fineness of classification screening can be adjusted, so as to obtain a variety of qualified products with different specifications.

Eight big advantage

1, product diversity is strong, RFLM series grinding host equipped with high efficiency multi-rotor classifier, can produce finished products particle size range, 2μm range of 30%~60%, D97=7~45μm, specific surface area of 20,000 00cm²/g, and D97=7.0μm products can be directly produced by the host.

2, with excellent design match, the mechanical system with higher transmission efficiency, and adopt the United States honeywell or Germany Siemens high efficiency motors, as well as using high efficiency special fan, the characteristic curve of fan completely according to the condition to carry on the design of vertical mill, so RFLM series ultrafine grinding energy consumption are lower than those of the same type of roller mill energy consumption, Long-term operation will significantly reduce the cost of electricity for enterprises.

3. The ultrafine powder produced by the host machine has the advantages of narrow particle size distribution, adjustable 2μm content, higher profit value of finished powder and good shape of single particle after classification. It is highly competitive and can be applied to higher end fields.

4. The optimized and improved grinding wheel, grinding disc, flow diversion system and internal circulation system have the highest grinding efficiency. Compared with the same type of products at home and abroad, the output is 10~20% higher.

5. The mill body improved by our company can operate under low vibration, which is lower in vibration and noise compared with other brands' products in mainland China.

6, with high reliability in the industry, classifier without filling and maintenance, often years without maintenance, durable, roller system for many years without maintenance, vertical mill maintenance times a year, far more than at the bottom end of the roller system, the structure of the reducer adopts planet vertical mill is special reducer, reduction gear with German kling berg spiral bevel gear, Torque and performance far exceed the commonly used American Gleason spiral bevel gears in the industry, gear materials using DIN standard 18CrNiMo7-6, to ensure high performance and long service life. Small reducer all use Germany SEW or Japan Sumitomo brand, high bearing capacity parts all use the United States TIMKEN bearing, high speed classifier part all use the world famous Sweden SKF, Germany FAG bearing, to ensure the long-term stable operation of the part. The driving part of the motor adopts the inverter products of Yaskawa Electric Co., Ltd. which are recognized in the industry as having high performance and high reliability.

7, super wear resistance, rui FengLi grading grinding wheel with high wear-resisting material and heat treatment technique, life far more than the same industry products, grinding wheel wear parts, wear parts for the mill USES the industry is well-known manufacturing plant, high wear-resistant alloy manufacture, can ensure worn in barite and talc industry maintain a high level of wear resistance for a long time, save the wear parts replacement cost for the user, And it reduces downtime.

8, intelligent, full of PLC control, touch screen operation, the system can realize full automatic operation of vertical mill production line, and real-time display and save a lot of running data, such as speed, temperature, pressure, differential pressure, and can according to the system pressure parameters, various points collected differential pressure parameters, current to realize automatic feeding operation, such as the industry leading technology, Most vertical mill products can only be manually controlled by observing the parameters manually. The powerful degree of automation makes the otherwise complex operation of the vertical mill so simple. And can connect to the Internet, remote control, remote fault analysis and processing, big data analysis.

previous:none